One of MAKO’s biggest passions is attending and contributing to tradeshows and exhibitions all around the world! We take our love for product design and manufacturing seriously, which means we hop on any chance to see the newest innovations in product design or manufacturing from innovators everywhere.

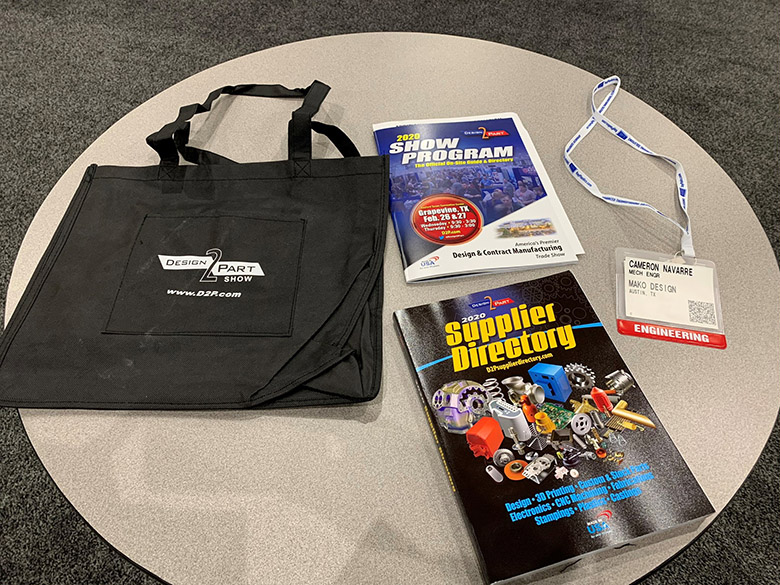

Attending different trade shows is a great way to connect with others who are equally as passionate and share our interests in the fields of design and marketing. This year, Cameron, our Mechanical Designer from our Austin office, went to the Design-2-Part Show to learn about new manufacturing services, sourcing services, and new technologies.

Cameron was super excited to learn about novel companies that can help provide the best services in manufacturing, material sourcing, and new technologies to collaborate with MAKO Design + Invent’s efforts in creating and getting the best materials and services for making the next best consumer products! Keep reading to learn more about Cameron’s experiences at the Design-2-Part Show 2020!

Design-2-Part Show as a Mecca for Manufacturing Services

The Design-2-Part Show is one of America’s longest-running manufacturing trade shows for sourcing custom parts, manufacturing services, and design. This unique show offers design and manufacturing fans the opportunity to connect and give a space to present their manufacturing services to others to other enthusiasts.

At the show, you can expect the opportunity to meet local and national job shops and contract manufacturers face-to-face to find new suppliers, learn new technologies, compare processes, and reduce your manufacturing costs overall.

Over 300 different kinds of processes are featured in order to offer the best and most unique resources in design, sourcing, and manufacturing. Some of the featured processes include CNC machining, stampings, castings, sheet metal fabrication, injection moulding, prototypes, springs, finishing, packaging, CAD/CAM software, assembly, and more!

Cameron’s Experience at the Design-2-Part Show

As one of our mechanical designers, Cameron is generally interested in learning more about what manufacturing services and technology are available in order to help build and source special materials and services to help create our intricate and detailed product designs!

After the show, Cameron was happy to share some photos of the exhibition, some highlights from the show, and what he found most interesting about the show.

At MAKO, we are well-equipped with many 3D printers to help us create pieces, parts, and prototypes for our clients’ designs. Thus, it was only natural for Cameron to visit and learn more about the newest 3D printing services that were on display at the show!

Cameron noted that after talking to the different stalls offering 3D printing services and information, metal 3D printing equipment is starting to become more affordable for smaller vendors who are now beginning to offer it as a service.

In the realm of sourcing, Cameron noted that after speaking with a company specializing in part sourcing, they emphasized the instability they’ve dealt with regarding Chinese vendors – a huge resource within the sourcing and manufacturing services world – due to tariffs and the recent coronavirus outbreak.

To deal with this instability and keep providing fast and quality services, they’ve begun to shift their production focus to the US, Mexico, and European-based facilities in response. Cameron learned that a lot of vendors are working to become flexible enough with their operations to accommodate production volumes from small prototype runs (<100) to larger-scale production runs (10K+).

Finally, looking back at all that Cameron had learned and seen at the show, he noted that the sheer number of US-based, mostly Texas-located vendors at the show reminded him of the available opportunities for potential local product production.

The vendors at the show were transparent in discussing the higher costs associated with their manufacturing services in comparison to overseas vendors but were also quick to point out that the many benefits to keeping production local include easier communication and having accessibility towards the oversight of the production – a huge factor in manufacturing and sourcing.

If you have a great new invention idea and you’d like to learn more about this process, get in touch with MAKO today, and we can set you up on a call with our product strategist!

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent!