When you work with MAKO Design + Invent, you can rest assured that our qualified and world-class team is well-equipped to bring your ideas to life! Each MAKO team member employs their own unique methods and strategies when approaching product design to contribute highly innovative products to the market.

No matter the project, we ensure that each design is of the highest quality and as aligned as possible with our client’s vision in the most cost-effective manner possible.

We receive a lot of questions about how our team likes to work and approach design, which is why we dedicated this blog to explaining some of the core factors our Austin-based product design specialists consider when approaching a project and throughout their design process journey!

Consideration #1: Having Detailed Design Constraints

Our product design specialists in Austin, Texas, believe that design constraints are an especially important factor to take into account when beginning the design process. Providing detailed design constraints can help give the designer a clearer image of what they need to prioritize from initial sketch design to prototyping.

We always ask our clients to be as specific and detailed as possible when describing what features they would like their product to have and how they expect it to look. This ascertains that what we deliver is above and beyond expectations.

Detailed design constraints typically include the ideal materials the product will be made from, as well as other functional details such as how the product should function, how the user will interact with the product, cost limitations, and quality standards.

The Total Design Model

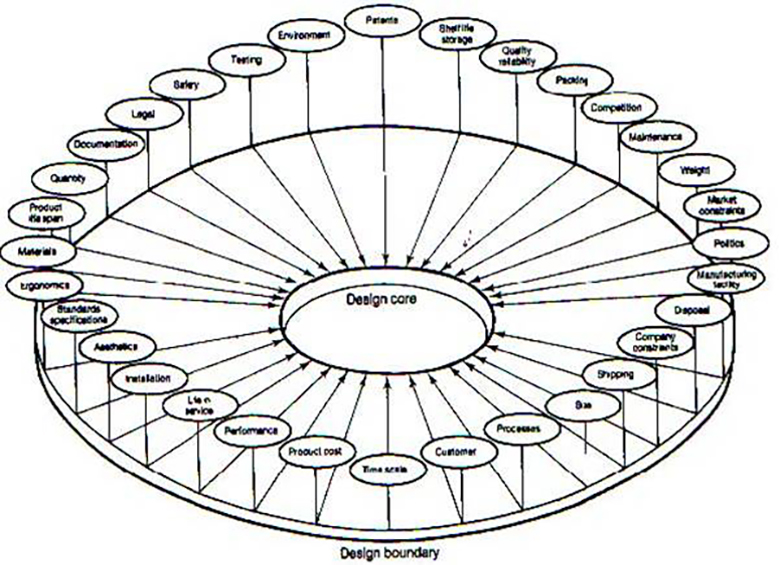

A common strategy that our product design team in Austin, Texas, use when ensuring design constraints are met is the ‘Total Design Model’ by Professor Stuart Pugh. This model allows the designer to clearly visualize all of the factors that may influence the design of the product and identify which factors must be given greater attention throughout the design process.

Having all of these factors clearly displayed helps designers figure out how to balance all of them and manage which will influence a design the most. This approach also ensures that factors such as cost, ergonomics, and the environment the product creates are not weighed too heavily over one another so that every factor is equal.

This image best represents the total design approach. Each oval represents a different factor. You can imagine the design like a circus performer balancing each plate, ensuring that nothing is dropped. At certain times, some plates – factors – will require more attention than others depending on the design stage, but by the end of the design process, the plates should collectively result in a balanced design.

Consideration #2: The Above and Below-the-Line Criteria

Simply put, our product design specialists in Austin, Texas, explain the above and below-the-line criteria as detailed specifications of what each client expects from their design. The above-the-line criteria explain the characteristics and details of the qualities, aesthetics, and visual interface between the user and product, materials, ergonomics, and function.

Essentially, the above-the-line is all about the physical and visual.

The below-the-line criteria focus on the product’s performance, functionality, components, ease of assembly, and build quality. Therefore, the below-the-line criteria are all about how the product is made and how it will work.

Consideration #3: Qualitative and Quantitative Testing

A clever practice that our product design team in Austin frequently employs is testing a product in a multitude of different ways in order to ensure that the design is headed in the right direction. Although there are a couple of different ways that one can test their product, two important and widely used tests that the MAKO team likes to integrate into our design process are qualitative and quantitative testing.

The primary role of qualitative and quantitative testing is that it enables designers to consider both overarching aspects of a design when selecting materials and processes, as well as considering the manufacturability of the product in relation to its proposed design specifications.

Quantitative testing examines the project’s objective and measurable criteria. This helps assess specific performances and measurable objectives, such as the product’s maximum and minimum desired weight, hardness, ductility, and malleability.

Qualitative testing assesses the quality of a defined aspect of the material specification. This form of testing is more subjective to the specific design details of the projects. Examples of qualitative testing include looking at how aesthetically pleasing the material of the product will be, whether it will be recyclable, a certain colour, and other considerations for its debut within the market.

Consideration #4: Specification Criteria

No matter how simple or complex a project is, at MAKO, our product design team in Austin, Texas, want to get as many details as possible regarding what our clients expect from their products. Providing specification criteria is integral as it allows the designer to compile a list of goals that the final design must achieve.

The best approach to developing your specification criteria is to create a checklist that our designers can refer to and review while they are working on the project.

Your specification criteria should centre on your product vision, a.k.a. the finished product you want to see at the end of your journey with us. It will help validate your invention idea and should include a list of statements that reflect your findings from the research you conducted for your product, as well as what your design will achieve or solve.

It’s important to remember that when you create your specifications criteria, you are not so exceptionally specific about what you want your design to achieve that you restrict yourself from innovative ideas. Having overly simple criteria is also not good. Essentially, the goal is to create a clear list of things that your product should be able to do.

If you have a great new invention and you’d like to learn more about this process, get in touch with MAKO today and visit our website to find out more. Or feel free to give us a call at 1-888-806-MAKO, and we can set you up on a call with our product analyst!

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto*). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent! *NOTE: Engineering services are provided exclusively by our USA-based engineering team