The world of prototyping is complex and can be challenging to new inventors. A good way to wrap your head around it is to improve your understanding of the lingo and constantly educate yourself. Today, we will offer some insight into iterative prototyping – one of the most common prototyping methods – and why you should use it to build your next product.

Iterative prototyping allows designers, entrepreneurs, and engineers to swiftly create designs and evaluate how useful or efficacious those designs are. It is particularly useful in helping a company or inventor increase conversions, improve usability, and convince stakeholders to invest in your product early on in the product development process.

This process entails designers rapidly creating a series of “rough drafts” of your product and gathering feedback from a group of end-users before finalizing the design. By testing out different ideas through various working prototypes, you can identify and perform multiple improvements to your design after one cycle of testing.

The critical part is not the product itself but the feedback you receive about the product design and the consumer experience!

Gather Feedback Earlier in the Product Development Process

In traditional prototyping, designers finalize the design and create the prototype based on that design before allowing end users to test the product. Iterative prototyping, which we use at our Toronto-based product design firm, allows you to evaluate if you’re on the right track earlier in the process.

At its core, prototyping is an iterative and communication-driven approach to product design. It’s based upon the idea that you’re not going to get everything right the first time around – and that’s OK.

With each rough draft of your product design, iterative prototyping allows end-users to test the prototype and provide feedback. Based on that feedback, designers can adjust the prototype and repeat the testing if needed.

Essentially, iterative prototyping allows you to include the customer experience much earlier in the design process. This allows for a more informed and smooth process once the product is launched.

Saves Money and Improves Efficiency in Product Design

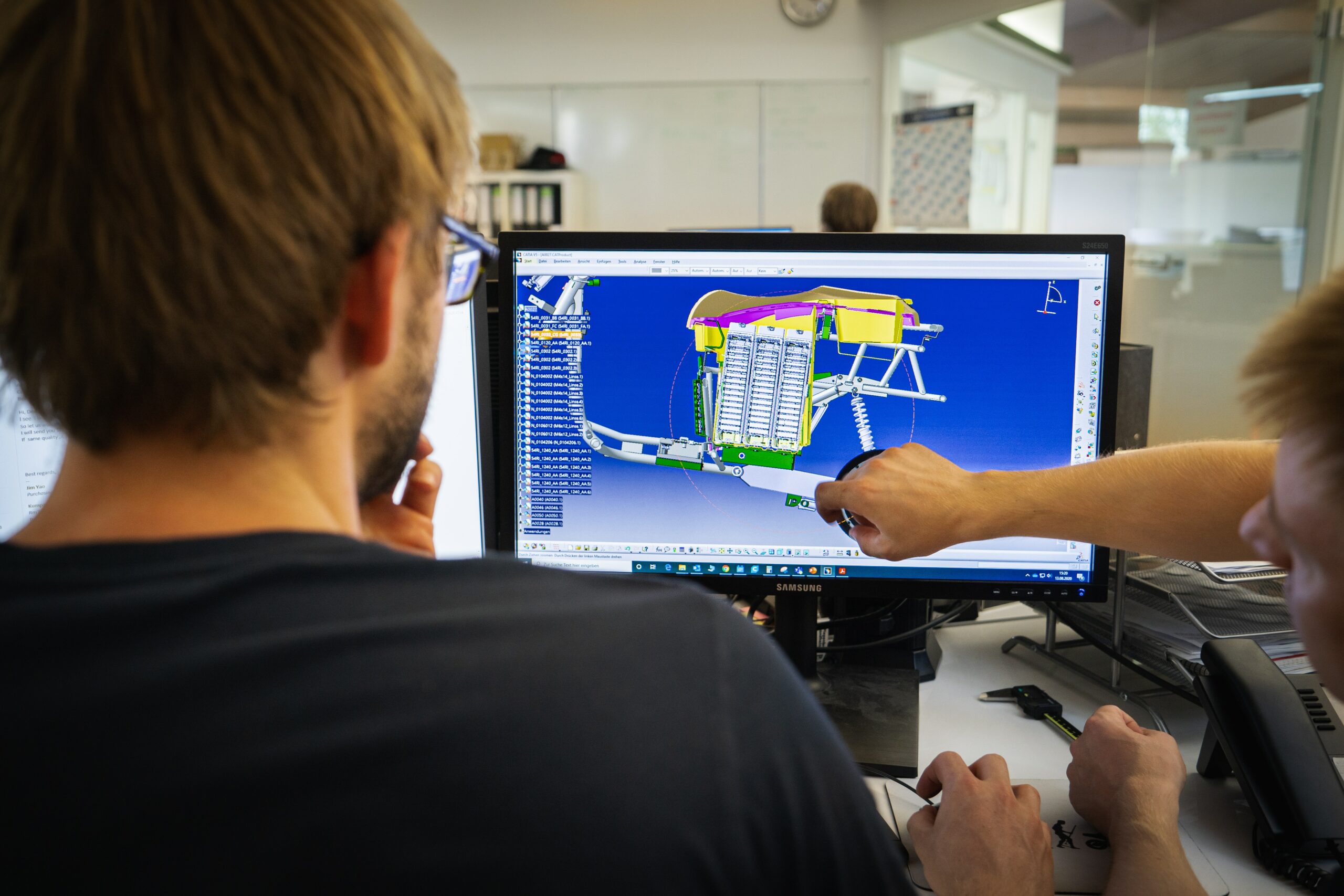

The iterative design process relies on cost-effective tools like CAD software and rapid prototyping technology, such as 3D printers or CNC machines. These tools make it easy to produce multiple prototypes at relatively little cost.

This is often more cost-effective than pooling a large segment of your resources into a single prototype, especially if that prototype ultimately doesn’t meet the needs of your end-user. You would have to repeat the whole process! You will also spend less time overall on the product development process, which saves labour costs and speeds up ROI.

Iterative prototyping also allows for the swift creation of prototypes. The goal is to get a working prototype of the design as quickly as possible so that engineers can identify and fix potential mechanical problems, material challenges, or other details that can’t be easily foreseen during the design stage.

At our Toronto product design firm, we regularly use iterative prototyping and have saved time and resources for multiple clients.

If you have a great new invention and you’d like to learn more about this process, get in touch with MAKO here and visit our website to find out more. Feel free to give us a call at +1 (888) 806-6256 (MAKO), and we will set you up on a call with our Senior Product Strategist!

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto*). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent! *NOTE: Engineering services are provided exclusively by our USA-based engineering team