Building

Intelligent Innovations

and Moving Experiences.

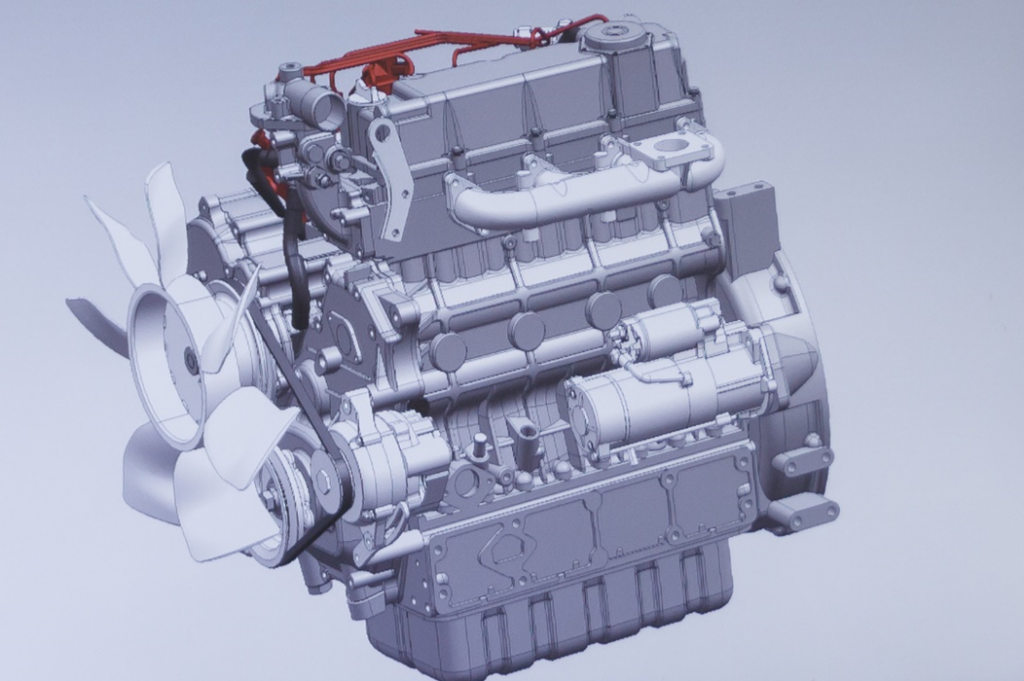

Believe it or not, mechanical engineering applies to almost everything that moves or can be moved. From the inconspicuous wheel to the roaring internal combustion engine, mechanical engineering services are important to our daily lives. This is how it should be! The purpose of a mechanical engineer is to help build technologies that make our daily lives easier. MAKO’s mechanical engineers take that purpose a step further. With an intense desire to delight and perfect, our engineers’ goal is to build products that make customers go from, “I want that,” to “I need that.”

Have a product idea?

Let’s chat.

What are Mechanical

Engineering Services?

Mechanical engineering is the process of calculating how environmental factors, conversion of energy, materials used, internal and external forces, and the product manufacturing process all affect the final product and parts in terms of durability, mobility, and functionality.

Think about some of the products you use every day. The joy of a smooth driving experience is thanks to mechanical engineering. The convenience of heating up your favorite leftovers in the microwave is thanks to mechanical engineering. The exhilaration of racing down a mountain on a responsive and stable bike is thanks to mechanical engineering. The relief of cool air from an air conditioner on a sweltering summer day is, you guessed it, thanks to mechanical engineering. That’s the importance of mechanical design and engineering. It’s the precise science required to build products that fit your vision and exceed your user’s expectations. If you’ve got a product with a moving part or needs to be manufactured, you’ll need a mechanical engineer.

Mechanical Engineering Services

MAKO’s end-to-end mechanical engineering capabilities include the following services below and more. Have a question about these services? Feel free to contact us with your mechanical engineering inquiries.

- Mechanical design

- Materials and thermal engineering

- Fluid mechanics

- Production-ready CAD

- Simulation and prototyping

- Schematics and specification documentation

- Additive manufacturing

- Pre-production, tooling and optimization

How Mechanical Engineering Services Work: Our Process

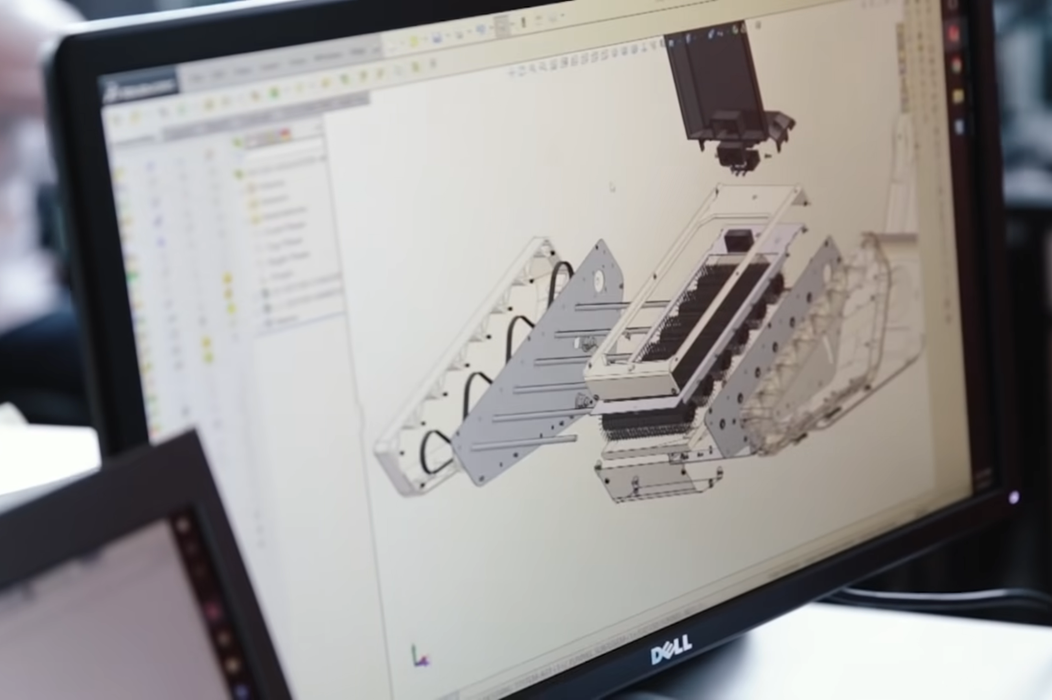

Mechanical engineering is an iterative process and starts as soon as MAKO works on the sketches of your invention in the early in our product design services and industrial design services phases. As we progress from visual design to engineering, we’ll finalize the desired size, shape, and structure in the sketches, and begin to build CAD models to visualize your invention in a 3D space while incorporating the specific engineering requirements. To put it simply, you can think of these CAD models like the 3D blueprints for the prototype and eventually the production version of the product. And with these CAD models, the MAKO team will be able to simulate how your invention works in the real world and visually communicate with you any mechanical engineering considerations such as stress, weight, durability, and performance. That way, we can collaborate and make any adjustments to optimize the CAD to your liking before prototyping and manufacturing.

1. ROUGH PRODUCT SKETCHES

IDEATE / CONCEPTUALIZE / DRAFT

An iterative and creative design process with the objective of visually communicating each of the inventor’s product features inside their overall visual design of the product as a whole. Together with our design and engineering teams, you and MAKO will evaluate these individual parts and the overall design theme to ensure the user experience, functionality, and aesthetics are aligned with your product vision and business objectives. This sketch phase, although rough, is a very powerful way of bringing together a number of highly intelligent minds to find the best draft solution for your product.

2. REFINED INVENTION SKETCH

EVALUATE / CONSOLIDATE

Based on the rough sketches and ideation prior, the refined product sketch phase puts together all of the pieces and the overall design language into one product sketch. This allows our designers, engineering team, and the inventor time to deeply reflect on the product as a whole and make any final edits or adjustments before going into the next CAD Design phase. Since edits are relatively quick in the sketching phase, it’s best to use these phases to make any adjustments before getting into the heavy lifting work of subsequent CAD design, engineering, and prototyping phases.

3. 3D CONCEPT CAD DESIGN

CAD / RENDERINGS

The CAD design phase is taking the refined sketch from above and then using state-of-the-art 3D CAD software to build the initial conceptual CAD design of your product. Even though this is just conceptual at this point, at MAKO, we start the building of these models with full manufacturing-grade top-of-the-line software such as Solidworks Premier or Fusion360. This requires more technical expertise; however, it makes the design and engineering process far smoother, and far easier to jump into manufacturing (and creates far more product value in the design along the way). Also, we’ve curated a library of components and experience from over 1,000 product designs, all developed in-house, so we’re extremely efficient and effective at 3D CAD Design as it is the key part of the mechanical and electrical engineering process.

4. SIMULATION ANALYSIS

ASSESS / OPTIMIZE

The question we’re trying to answer here is: “Can we make it better and more cost-efficient?” This phase is all about identifying the limitations and improvement opportunities through rigorous 3D virtual simulations of the product in various static and dynamic settings. For example, structural simulations will help us pinpoint the maximum loads of your product. Kinematic simulations will let us know how smooth and efficient it is to operate your product. Identifying these critical mechanical engineering elements is the key to building functional prototypes, reliable manufacturing runs, and getting your ideal version of the product in your customers’ hands.

5. PROTOTYPING

BUILD / MEASURE / LEARN

The purpose of the CAD is to confirm that the product design is feasible and functional from a virtual perspective. The product prototyping phase gives you the opportunity to hold and use a tangible product to learn how the product looks and functions in the real world. Prototyping also gives you the opportunity to refine and perfect the final design to minimize costs and risks before going to full production. Whether it’s iterative, parallel, rapid prototyping, or our very own Smart MVP process, our prototyping processes are designed to help ensure you’re ready for user testing, investment pitches, crowdfunding, and everything in between.

How MAKO’s Mechanical Engineering Services Company

Can Build Your Business

ENGINEERED TO COMPETE WITH THE BEST

A well-engineered product is just the baseline at MAKO. Today’s hardware products are more compact, more efficient, more intuitive, and more connected to the world than ever before. As a design firm focused on the entire end-to-end development process, we’re here to help you carefully navigate your specific niche to discover propulsive opportunities to disrupt your market.

ENGINEERED FOR SUCCESS

Many of MAKO’s experienced engineers and designers come from senior positions in Fortune 500 product companies including Dell, Nike, Bose, and Boeing – folks who love a challenge. So whether it’s a question of structural integrity, the flow of mass transfer, material selection, energy conversion, or simply just trying to fit all the parts in a compact package, we’ll come up with a solution you and your end-users will love.

ENGINEERED FOR YOU

Even if you’re not particularly science-savvy, MAKO’s engineers will help make sure you understand exactly how, what, and why each material, part, or subsystem is necessary and contributes to the overall success of your product and manufacturing process. As part of our end-to-end product development services, we want you to be confident in every step of the process within a timeline that works for you. Because that’s what collaboration is all about.

Mechanical Engineering Consulting Services Engineered to Work for You

MAKO Design has spent over 20 years creating, testing, refining, and perfecting the mechanical engineering process required to create global caliber products, specifically for startups, small manufacturers, home inventors, & eCommerce brands. Through our intense focus specifically on product design services for small businesses, we ensure perfect alignment with your product vision and help you succeed in every way. Our product design services are tailored to designing your product to a modern and top-tier caliber while also being able to execute quickly and efficiently, all at small business budgets. We created this product development niche back in 1999, and we’re still leading it today focusing on that same business model over 20 years later.

FOR HARDWARE STARTUPS

Whether you’re an early-stage startup or getting ready to scale, we’re here to transform your idea into a product design to help you disrupt the existing market, along with the many product market connections you’ll need along the way. MAKO is your one-stop-shop for it all, in addition to connecting our clients with some of the industry’s leading players in the hardware startup space.

FOR SMALL MANUFACTURERS

We are the original product design services firm tailored to small product businesses, so why not work with the best for your next big product? Whether designing something completely new, revitalizing your existing products, or improving something that already exists, MAKO provides world-class design at small business pricing and timelines.

FOR ALL HOME INVENTORS

No ask is too big, no detail is too small. We’re here to collaboratively design your product for success. As a new inventor, MAKO has the most comprehensive set of support services, industry connections, and guidance to help your product be a huge success. We guide you through the entire process, then set you up with direct connections to some of the best product sales brands on earth.

What’s Next after Mechanical Engineering is Done?

If your product requires electrical product development, such as printed circuit boards (PCB), MAKO will also take care of electrical engineering. Indeed, not every invention needs electrical engineering. Because it’s not a question of mechanical vs. electrical engineering, it’s about determining if electrical components will enhance the end-product to deliver a valuable experience for the end-user. Once the mechanical and electrical engineering processes are complete, most of our clients will transition to the prototyping and manufacturing phases. Arguably, prototyping is the most exciting part of our product development process as these are the first steps of transforming your product from a digital file to the birth of a real, tangible product you can use and feel in your hand. In addition to manufacturing, the two other options are to license your product or raise funding. All three main options are outlined below:

OPTION 1:

CONTINUE DEVELOPMENT

TO MANUFACTURING

The way most new inventions become successful products is to get to manufacturing and selling products. Once engineering is done, MAKO Design can complete the prototyping and manufacturing of your invention for you. We are a one-stop-shop from sketch to production then to sales. Half of our products are physical inventions, the other half are electronics products. Either way, we’re a full-stack in-house development firm. Below is a full list of all steps to get your product to production and then get your product out to market buyers!

OPTION 2:

LICENSE YOUR PRODUCT

TO A BRAND

Some inventors just want to get their product designed to a point where they can then license their invention idea to an existing product brand. Either way you go, completing world-class product design is a critical first step. If looking to license directly after design, MAKO would then set you up with a patent attorney so you can protect your IP before pitching your idea to licensors. Keep in mind that the further you develop your product, the higher the probability of licensing, so you may want to use MAKO’s prototype development services to have a MAKO engineer and/or prototype your design before you start pitching to get a licensing deal.

OPTION 3:

RAISE INVESTMENT TO

CONTINUE DEVELOPMENT

Raising money is a very normal part of getting a hardware product off the ground, and with MAKO’s help, anyone can do it! In fact, half of MAKO’s clients don’t start with enough funds to complete development and manufacturing. First and foremost, before raising any money, even from friends and family, it is essential that you complete at least the product design portion yourself. Even then, the further you push into engineering and especially prototyping, the better you look to investors, the more money you can raise, and the less equity you will have to give away.

How Mechanical Engineering Fits into MAKO’s Overall Product Process

1. PRODUCT DESIGN

This is the first and most important step in the product development process. This is the foundation of all product development to come, so is critically important to have it done right.

2. ENGINEERING

You are here! Mechanical engineering and electrical engineering (for those products with electronics) are the detailed work on the CAD to ensure that all components of the product design work cohesively, reliably, and predictably.

3. PROTOTYPING

Before the product reaches the market, it’s important to test the form and functionality with a prototype. Prototypes are also a great way to generate traction for marketing, pre-sales, crowdfunding, and financing initiatives.

4. PATENTING

We have preferred connections and pricing with a network of patent attorneys to help our clients with all things related to IP (Intellectual Property) protection. Our clients get quality patent referrals, affordably through our network of US and Canadian patent attorneys.

5. MANUFACTURING

Once the prototyping and engineering are complete, tested, and refined, the product is ready to move to production. This may happen after preselling through crowdfunding, or before selling if you choose to sell direct to buyers once you have inventory in stock.

6. SELLING

MAKO Design has many connections to help our clients launch and sell products. There are three main options: Pre-selling through crowdfunding, bulk order sales directly to wholesalers, distributors, retailers, and/or direct to the end-customer.

Mechanical Engineering Services: Frequently Asked Questions

Here are a few of the most frequently asked questions about MAKO’s mechanical engineering services. Don’t see an answer to your question here? Feel free to contact us anytime with your inquiries, read our blog for hundreds of articles related to mechanical engineering and other product design services, learn about the entire end-to-end process with MAKO’s free invention kit, or check out the industry’s largest podcast: The Product Startup Podcast.

Mechanical engineering is the application of mathematics, material sciences, and physics to understand how certain forces interact with one another with the goal of designing and manufacturing objects that accomplish specific tasks reliably and efficiently.

Mechanical engineers will help research, design, develop, analyze and manufacture products or parts based on their client’s aesthetic and functional requirements.

Design for Manufacturing (DFM): Designing parts and products specifically for efficiency and quality

Mechatronics: The integration of mechanical and electrical engineering.

Materials Engineering: Like the development of composition materials.

Fluid Mechanics: The effects gasses and liquids may have on your product

Solid Mechanics: The effects of forces on solid objects

Thermodynamics: Such as the combustion of fuels.

Let’s Chat

Use the form below to let us know how we can help.

We’ll get back to you within one business day.