The Intricate Process of Manufacturing a Product

The mind of an inventor is almost like an idea machine. Your brain produces a concept that sparks curiosity about a game plan for how to get a product made. The generator is product manufacturing. The process leading up to it allows you to deepen the brief and transform it to be ready for the market. If you are looking for a step-by-step guide to the looming question of ‘how do I get my product manufactured’, you have come to the right place.

Step 1: Research and Develop Your Idea

During this product development phase, it’s crucial that you evaluate the need for your invention idea and set a strong target audience. For instance; who is this product being developed for, what is the target market looking like right now, and what is your marketing plan?

When you take all of this into perspective, you will complete the necessary self-validation of your idea’s usefulness. You will now be ready to focus on the analytical phase of your idea. This includes assessing the desired function, which materials to use, and how it will run smoothly for a real-world consumer, as well as conducting rudimentary concept sketching and detailing core features.

Once the prototyping chapter begins, these notes and concept sketches will be exceptionally useful.

Step 2: Protect Your Property

Before moving forward and or employing other resources, it’s important to form an exclusivity agreement. This will help provide a degree of legal protection, so another company and or a manufacturer can’t use or sell the product through any medium.

It’s also important to really investigate all aspects of intellectual properly. For instance, it is important to check if you can copyright the design that is created or if the company’s name needs trademark protection.

At MAKO, we work with the best intellectual property attorneys in both the US and Canada for our clients to inform the industrial design, prototyping, and product manufacturing process, and beyond.

Step 3: Make a Prototype

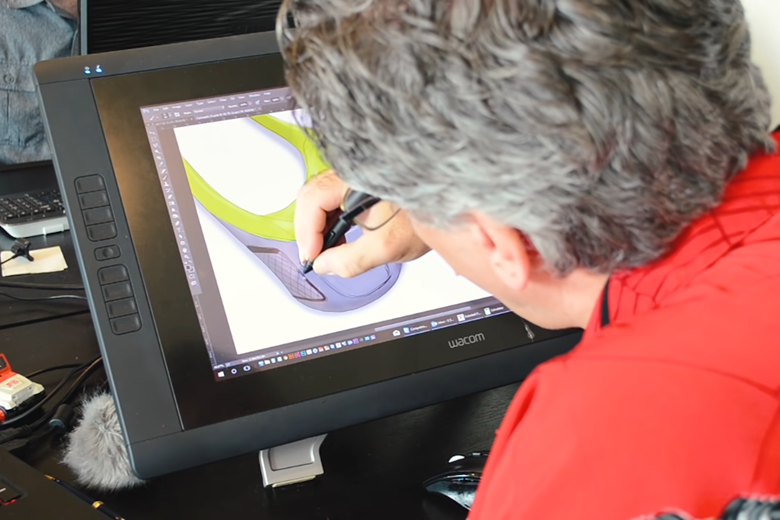

Bringing your idea to life through prototyping is exciting but, more importantly, it affords the opportunity to test and refine the concepts drafted during the research and development stages.

The philosophy behind this is to achieve a basic understanding of requirements and explore different variations. CAD (computer-aided design) assists in activating these elements through simulations. The prototype can either break down into a whole or isolated. Not to mention, build individual elements. This depends on what is the most suitable for your product.

With that being said, consulting with a trustworthy design firm like MAKO is the glue that holds this process of product prototyping together. It’s especially important as prototypes at this stage can also be launched to a small group of consumers and industry professionals for early feedback.

Step 4: Find a Manufacturer

When working with a manufacturer, it’s important to build a solid relationship. Therefore there are many factors to consider. For example:

- Excellent reputation + certification – You can consult former and current clients. Not to mention, you can check in with local and international Better Business Bureau‘s.

- Ethical compliance – This includes labor rights and environmental impact.

- Expertise – The manufacturer has worked with or has knowledge of similar product types or the select demographic you aim to sell to.

- Order Capabilities – Does the manufacturer have the capabilities to supply the amount needed? Also, does the manufacturer have the manpower for expansion down the road?

- Costs – Is the quoted numeration reasonable? And does it cover shipping?

Step 5: Obtain Multiple Quotes

Now, it’s time to dive deeper into the potential prospects. This means identifying and asking certain questions that are imperative to have cited when moving forward. For example, if there are any payment conditions, sample costs, and even offers for the first batch of minimal order quantities. The information collected at this step will support subsequent decision-making processes.

Step 6: Order a Sample

At this point, your invention will be ready to form into a small or singular quantity. This method ensures that the final product has met its expectations before performing a full production.

When ordering a sample, the process is quite straightforward. Typically, you will need to send in a request with the prototype to the manufacturer representative. They should follow up with any instructions or respected procedures. The manufacturer will then use it as a foundation to curate the sample product.

Step 7: Test Prototypes + Final Iterations

Once the samples are received, it’s time to conduct a test run in an environment that they will be used in! This phase is almost like playing a local in a new city. Your product will face a variety of different outcomes to determine interlinkage and durability.

It would also be a great idea to bring back a focus group of industry consumers and inner circle connections. They may view it from a more unique perspective and provide critical feedback on improvements that can be made to optimize the user experience.

Once you are satisfied with your prototype’s functionality and physical form, you can continue production, at whatever rate makes sense for your budget and the success achieved with the initial sample products!

Manufacturing a Product: Frequently Asked Questions

How much does it cost to manufacture a product?

As every product needs different forms of attention, the cost can vary. However, you will be provided with an estimate from either your product design team or a quote from the manufacturer.

What to look for in a product manufacturer?

After deciding on the primary characteristics of the product and creating a prototype with a design team, it’s now easier to determine the best manufacturing option. However, an excellent reputation and a high level of expertise regarding the market you would like to penetrate are generally what you want to look for.

What should I do before manufacturing a product?

First and foremost, it’s important to consult with a design firm like MAKO with over 20 years of experience working with clients like yourself, as well as manufacturers. Ultimately, you should research the materials your product needs, create a prototype, conduct testing, and receive quotes from prospective manufacturers prior to the commencement of manufacturing.

If you would like to learn more about manufacturing inventions from MAKO’s Senior Product Strategist, take a look at one of our archived entries here.

Where can a product be made?

From product development right to patenting, you will have an in-house team right here at MAKO. We work on over 150 different projects per year that range from simple products with one utility, such as the Comfycup, to complex designs that require mechanical and electrical engineering, such as the CarGenerator. There is nothing that you can’t achieve by partnering with us!

Final Notes

As we have learned, the more we feed research and testing to the generator that is product manufacturing, the higher the quality of the final product that results from your invention idea will be regardless of the niche market it targets or the complexity of its design.

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto*). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent! *NOTE: Engineering services are provided exclusively by our USA-based engineering team